Our focus on sustainability continues with our discovery of a new, more sustainable bag for shipping Firebolt products.

At Firebolt, we respect, preserve and conserve the precious natural resources all around us and strive to ensure our products meet the highest eco-friendly manufacturing standards.

Our commitment to sustainability goes beyond our own operations. We are also committed to helping our clients meet their sustainability goals and recently announced our Trace Firebolt program. This initiative provides for eco-friendly disposal of Firebolt products at the end of their lifecycle and focused sustainability efforts that will yield carbon neutrality and reduce hazardous materials in product production.

The Problem: Non-environmentally sound shipping bags

One of the most significant contributors to our carbon footprint is shipping. Firebolt ships products worldwide every month, so this is a big part of our impact on the planet. Our Sustainability Team recently evaluated our shipping bags. We shipped over 100,000 products out of our Wixom headquarters alone. Each of Firebolt’s Krystals lighted signs utilized poly bag packaging made from polyethylene. Standard poly bags are versatile but not environmentally friendly. Many of the options we researched have been cost-prohibitive or unavailable in mass production volumes.

CHALLENGES IN FINDING A SUSTAINABLE SHIPPING BAG

We did an in-depth evaluation of bags on the market and came across many challenges.

1.) Lack of domestic manufacturers of biodegradable bags we could use, so we had to look overseas.

2.) Most sustainable options were at least double the cost of our current solutions. Affordable solutions didn’t have a self-adhesive seal, which we needed to reduce labor otherwise spent on manually taping.

3.) Suppliers we found required high volume and minimum order quantities.

4.) Some products decompose too quickly and would break down while our product is still in the warehouse.

5.) The reviewed bags didn’t meet our requirements; they were biodegradable certified but not compostable. Many needed to be more durable or would scratch our products.

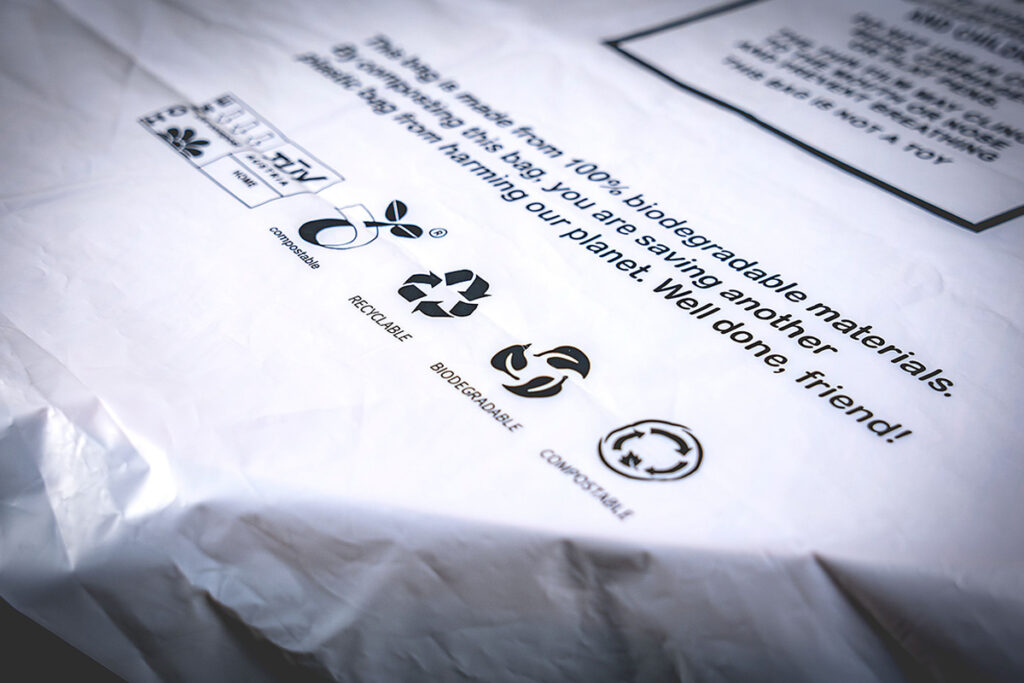

THE SOLUTION: BIODEGRADABLE AND COMPOSTABLE BAGS

The team was determined to find a solution—and they did. After an exhaustive search, the team sourced a fully compostable bag made from 100% biodegradable materials. The new bags were comparable in current costs and were compostable certified and included a self-seal tab, alleviating concerns about additional labor expenses. The bags addressed all of the other requirements we set out, including durability.

The new bags are made from biopolymers PLA+PBAT, replacing the previous polyethylene bags. The material is 100% compostable and can be recycled in certified facilities.

The shelf life of the newly sourced bag is 12-15 months. It decomposes within 3 months of being in the Earth. As an added bonus, there is a hole punched in each bag to minimize the risk of suffocation.

Although it took considerable time and research, we all agreed this was the necessary next step for not only ours but our customer’s sustainability journey. Visit here for more information on Trace Firebolt.